Par Marc-André Girard (@magirard)

Un dossier conjoint de L’École branchée et Carrefour éducation

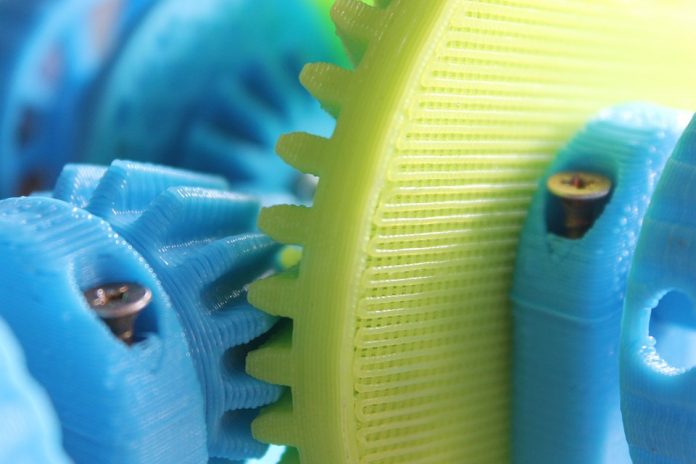

Le potentiel pédagogique des imprimantes 3D est immense. Bien que la technologie existe depuis le début des années 1970, le marché s’est grandement démocratisé depuis quelques années grâce, notamment, à l’expiration de plusieurs brevets sur les technologies employées à l’époque. Aujourd’hui, ces outils sont relativement abordables et, si la tendance se maintient, ils deviendront encore plus accessibles dans les prochaines années.

Des observateurs estiment que l’impression 3D envahira la technosphère pour la révolutionner et changer à jamais le rapport que l’humain entretient avec l’objet. L’impression 3D sera-t-elle le nouvel Internet? Envahira-t-elle les ménages américains et canadiens? Révolutionnera-t-elle l’aide aux pays en voie de développement? Deviendra-t-elle un outil incontournable dans les écoles?

Ce dossier vise à dresser un portrait technique de l’impression 3D et des possibilités actuelles en milieu scolaire. Pour sa réalisation, l’auteur a testé cinq modèles différents et s’est familiarisé avec la technique, ce qui lui permet de dévoiler quelques conseils importants.

Sommaire du dossier :

- Introduction : Petit guide de l’impression 3D à l’école

- Le potentiel pédagogique de l’impression 3D

- Impression 3D à l’école : par où commencer?

- « Impression 3D 101 » : le fonctionnement et les matériaux

- Cinq imprimantes 3D testées pour vos activités pédagogiques

- Questions fréquemment posées à propos des imprimantes 3D

Le potentiel pédagogique de l’impression 3D

Déjà, les applications médicales de l’impression 3D sont infinies. De l’impression de moules pour fabriquer des écouteurs intra-auriculaires jusqu’à la fabrication de prothèses pour remplacer des membres humains, elle s’est rapidement retrouvée au cœur de plusieurs espoirs d’amélioration de la qualité de vie humaine. Des entreprises du domaine de la santé s’évertuent d’ailleurs à tenter d’imprimer des tissus humains. La compagnie L’Oréal annonçait récemment qu’elle testerait ses produits sur de la peau humaine imprimée en 3D. Une firme d’impression de tissus humains en 3D, Organovo, a déjà débuté la commercialisation de tissus hépatiques pour qu’ils soient soumis à des études toxicologiques. Sous peu, il entamera la commercialisation de tissus néphrologiques, toujours destinés à des études médicales.

Les autres domaines de la santé d’y échappent pas. Autant en orthopédie qu’en dentisterie ou même chirurgie, les espoirs sont grands : instruments, implants, modélisation, prototypes, etc.

L’éducation n’y échappera pas!

Pendant que plusieurs estiment que l’impression 3D joue un rôle important dans ce qu’ils qualifient de révolution médicale, la question que nous nous posons est la suivante : quelles sont les potentialités pédagogiques des imprimantes 3D?

À l’origine, l’intégration des imprimantes 3D relève du modèle pédagogique STEM (Science, Technology, Engineering and Mathematics). Les applications étaient principalement liées aux sciences et aux mathématiques : utilisation de formules géométriques pour mieux visualiser des formes complexes, fabrication de pièces de robotique ou impression de modèles liés à la compréhension du fonctionnement du corps humain.

Le modèle STEAM (Science, Technology, Engineering, Arts and Mathematics) a rapidement bonifié le modèle STEM. Désormais, les applications artistiques ont rapidement émergé : elles permettent de créer des modèles de différentes œuvres de toutes sortes en plus, bien évidemment, d’être un nouveau rempart de créativité pour les élèves. Nous y reviendrons.

Enfin, les sciences humaines ne sont pas en reste. En géographie, il est devenu aisé d’imprimer des reliefs afin de modéliser, par exemple, les bassins hydrographiques ou encore de conceptualiser l’aménagement d’un quartier d’une ville. En histoire, il est très simple de reproduire divers outils utilisés dans des techniques ancestrales en plus de bâtir des monuments en fonction de diverses caractéristiques architecturales allant des maisons de terre des Vikings jusqu’aux grandes cathédrales européennes.

Impression 3D à l’école : par où commencer?

Différentes pistes pour aborder l’impression 3D à des fins pédagogiques…

De plus en plus d’écoles favorisent l’émergence de l’entrepreneuriat chez les élèves. Ces derniers peuvent fabriquer leurs propres objets qu’ils comptent mettre en vente. Désormais, seule leur imagination est la limite : ils peuvent fabriquer des boutons de remplacement pour un vêtement, un porte-savon, des outils, des montures de lunettes, des bijoux, des étuis protecteurs, etc. Des entreprises éducatives comme les Jeunes entreprises du Québec donnent la chance à des élèves ou étudiants de commercialiser leurs produits en créant une petite entreprise étudiante. Définitivement, les imprimantes 3D peuvent contribuer à faciliter l’émergence d’une culture d’entrepreneuriat en milieu scolaire.

Dans la même veine, au lieu de remplacer un objet dans son entièreté, pourquoi ne pas réparer ce dernier en imprimant, lorsque possible, la pièce brisée? Bref, la créativité est au service de l’entrepreneuriat. On cerne nos propres besoins et ceux de notre entourage et on s’efforce d’y répondre soi-même. Il en va de la redéfinition du lien que chaque humain entretient avec l’objet.

L’utilisation d’outils numériques de conception 3D augmente les possibilités artistiques. Depuis toujours, excluant les œuvres sculpturales, les élèves ont été habitués à concevoir en 2D, soit sur une feuille de papier, une toile, ou sur un support numérique. Désormais, il faut penser différemment, avec des outils différents. Par exemple, un logiciel comme SolidWorks est incontournable, car il gère la totalité du processus, allant de la création jusqu’à l’impression. Il permet également à l’utilisateur de créer des pièces 3D élémentaires assez facilement. C’est d’ailleurs un logiciel qui est utilisé dans plusieurs facultés de génie, permettant aux étudiants de concevoir aisément une œuvre tridimensionnelle et de la voir prendre forme.

De plus, combinées avec d’autres outils de pointe, dans un atelier de fabrication numérique ou dans un Fab Lab, les possibilités créatives sont décuplées. C’est le principe même des makerspaces, ces ateliers de fabrication numérique appelés à prendre d’assaut les écoles dans les prochaines années.

Certains fabricants d’imprimantes proposent des activités pédagogiques sur leur site Web, en plus d’un accès à leur communauté d’utilisateurs provenant très souvent du réseau scolaire. Bien évidemment, la plupart du matériel pédagogique créé est disponible en anglais.

Le premier Fab Lab au Canada, celui de Communautique (Échofab), offre un atelier de découverte de l’impression 3D à Montréal.

Également, il est possible de prendre contact avec d’autres entreprises qui vendent ou utilisent cette technologie. Par exemple, Voxel Factory donne des formations également, et ce, qu’on achète ou non une imprimante 3D. Ils offrent un service d’impression pour les besoins de fabrication ponctuels si on ne souhaite pas se doter d’un tel appareil.

« Impression 3D – 101 » : le fonctionnement et les matériaux

Avant d’aborder la question du choix de l’imprimante 3D, il y a un critère important à considérer : le filament. C’est un peu comme se questionner sur le type de cartouches d’encre pour une imprimante conventionnelle. Et avant de considérer le filament, il faut comprendre le fonctionnement intégral de l’appareil.

Fonctionnement

Par définition, l’imprimante 3D fonctionne de façon additive, c’est-à-dire qu’elle fait fondre l’une sur l’autre de très fines couches de thermoplastique qui fusionnent pour former l’objet conçu à l’aide d’un logiciel de conception tridimensionnelle. Ce thermoplastique est livré, la plupart du temps, en bobines ressemblant étrangement au fil de remplacement d’un taille-bordure et il est habituellement accroché derrière l’appareil, ce qui permet de prendre l’extrémité du filament et de la connecter au mécanisme d’extrusion à travers un tube. Le fil est fondu au fur et à mesure que l’imprimante fabrique un objet et la bobine se déroule. Ultérieurement, il faudra évidemment la remplacer.

Ces bobines sont, règle générale, vendues à un poids de 750 grammes de matériau et ledit fil thermoplastique qui y est enroulé présente généralement un diamètre de 1,75 mm. Contrairement à ce qu’on pourrait croire, le fil est rarement vendu à la longueur!

Les deux principaux matériaux utilisés par les imprimantes 3D en milieu scolaire sont l’ABS et le PLA (expliqués un peu plus loin). Ici, il semble important de mentionner qu’il n’existe pas de polymère idéal. Comme dans tout, il y a des avantages et des inconvénients à chacun. De plus, outre l’ABS et le PLA, plusieurs autres matériaux existent : le nylon, le ninjaflex et d’autres types de polymères.

L’ABS

L’acrylonitrile butadiène styrène, mieux connu sous l’acronyme ABS, est un plastique très présent dans nos vies. On n’a qu’à penser aux fameux blocs Lego ou à diverses pièces de plastiques sur de petits électroménagers à usage quotidien. Ce type de polymère est réputé pour sa solidité et c’est pour cette raison qu’il sert souvent de structure pour une pièce ou un objet. Sa température de fusion étant relativement élevée pour un polymère, l’ABS est peu affecté par les températures élevées.

Concrètement, un objet imprimé avec un filament d’ABS ne risque pas de se déformer s’il se trouve à proximité d’un calorifère, d’un électroménager, d’une lumière ou de toute autre source de chaleur domestique.

Grâce à sa solidité, il est possible de fabriquer des vis de plastique ou des pièces qui s’emboitent. Il est même possible de sabler légèrement la pièce.

Cependant, l’ABS a deux inconvénients majeurs. Dans un premier temps, tant qu’il n’a pas figé, il demeure fragile. C’est la raison pour laquelle l’impression est déposée sur un plateau chauffant ou, dans certains cas, réalisée dans une enceinte chauffée pour éviter les risques de déformation lors d’un changement rapide de température. Également, l’ABS peut dégager une odeur de plastique fondu. Les manufacturiers ne s’entendent pas à savoir si une ventilation est nécessaire et plusieurs recherches démontrent que les toxines libérées dans l’air sont près de cinq fois inférieures aux normes de santé publique aux États-Unis. Ceci dit, les recherches sont réalisées à des températures de fusion largement supérieures à celles employées par les imprimantes 3D à usage non commercial.

Le PLA

L’acide polylactique, ou PLA, est un autre polymère utilisé dans les imprimantes 3D. Sa particularité est qu’il est biodégradable puisqu’il est habituellement fabriqué à partir de fécule de maïs ou de résidus de canne à sucre. Cela en fait un matériau particulièrement prisé puisque son empreinte écologique est moindre que celle de l’ABS. D’ailleurs, le PLA est fréquemment utilisé dans les emballages alimentaires et dans les plusieurs instruments médicaux. Sa température de fusion est moindre que l’ABS. Cela signifie qu’un objet imprimé avec un filament de PLA risque de se déformer s’il se trouve à proximité d’un calorifère, d’un électroménager ou si on l’oublie dans la voiture lors d’une canicule en été…

Plusieurs estiment que le PLA est un polymère moins solide que l’ABS. Cependant, dans le cadre d’une utilisation à des fins pédagogiques, peu de projets pourront constater les limites du polymère. Bien évidemment, le PLA étant fabriqué à partir de matériaux organiques, l’odeur qui se dégage du plastique en fusion est peu dérangeante, voire même agréable. Si elle ne passe pas carrément inaperçue, une subtile odeur de sucré est perceptible, laquelle ressemble, selon certains, à une odeur de sirop d’érable.

L’impression de la pièce en PLA se fait sur une plaque non chauffée. Il est généralement recommandé d’y placer un ruban adhésif pour augmenter l’adhérence de la pièce. Certains choisissent de vaporiser du fixatif à cheveux pour maximiser cette adhérence. D’autres fabriquent une colle spéciale à cet effet. Pour l’avoir expérimenté, il est effectivement souhaitable d’utiliser le ruban et le fixatif pour faciliter la prise des premiers filaments imprimés sur la plaque. Aussi, une compagnie européenne a développé un fixatif dédié uniquement à l’impression 3D, le 3DLAC.

Vous pourrez faire vos propres essais, mais voici une combinaison qui fonctionne bien : le ruban bleu 3M 2090 de deux pouces de largeur (disponible dans la section peinture de votre quincaillerie préférée) et le fixatif 3DLAC en question. Une bonne adhérence du PLA dès le début maximise les chances de réussite de l’impression en plus d’éviter que la pièce ne tangue et, possiblement, abime la buse.

La bonne bobine

Les prix d’une bobine de fil PLA varient généralement entre 40 $ et 80 $ pour 750 grammes à un diamètre de 1,75 mm. Idem pour les bobines de filament ABS, lesquelles peuvent cependant être un peu plus chères. Bien souvent, les fabricants offrent un léger rabais à l’achat de plusieurs bobines (entre la demi-douzaine et la dizaine). Également, des compagnies autres que les fabricants offrent des bobines de filament à des prix inférieurs que ceux normalement recommandés. Habituellement, on peut envisager de payer une dizaine de dollars de moins.

Par exemple, la compagnie néerlandaise ColorFabb offre du filament d’excellente qualité, dans une multitude de coloris, et ce, à des prix avoisinants les 40 $. Ils offrent même des filaments contenant de la poussière de bronze recréant des œuvres d’art pouvant ressembler à s’y méprendre, une fois polies, à de véritables statuettes! Un dernier détail, et non le moindre, la bobine de filament ColorFabb est transparente. Cela permet d’estimer facilement la quantité de filament restante.

Voici deux choses à considérer pour épargner en achetant le filament. Dans un premier temps, la meilleure façon d’économiser demeure d’acheter plusieurs bobines dans une même commande. Il y a alors possibilité d’épargner entre trois et cinq dollars par item lorsqu’on en achète plus d’une dizaine. Informez-vous à votre revendeur. Deuxièmement, il existe du filament peu dispendieux sur des sites de revente comme eBay. Avant de faire un tel choix, qui risque d’abimer ou de boucher la buse d’impression, rappelez-vous qu’il est relativement compliqué de faire les réparations soi-même sur un tel appareil. Et les pièces de rechange sont onéreuses. Lorsqu’une buse bloque, les projets qu’elle doit imprimer bloquent aussi et des élèves demeurent dans l’attente. C’est à ne pas négliger. Bien souvent, les économies réalisées ne justifient pas les risques pédagogiques ou les réparations qui vous attendent.

Cinq imprimantes 3D testées pour vos activités pédagogiques

Dans un premier temps, il est important de comprendre que le marché des imprimantes 3D vient à peine de se démocratiser. Les appareils, bien qu’ils détiennent un potentiel pédagogique appréciable, demeurent une technologie qui sera appelée à évoluer rapidement. Par exemple, bien peu d’imprimantes permettent une impression à deux couleurs. Il est à prévoir que cela changera sous peu. Également, lors d’une utilisation intensive en milieu scolaire, il faut prévoir que des problèmes de durabilité risquent fort de surgir. En effet, les imprimantes qui suivent sont des appareils qui ne sont pas fabriqués pour un usage aussi intensif. Ce qui rend ces technologies intéressantes pour l’école, c’est qu’elles représentent un compromis entre la qualité et le prix.

Également, ces appareils nécessitent une bonne dose de patience. Bien que les imprimantes 3D soient paradoxalement simples et complexes à la fois, la clé demeure l’ajustement du plateau d’impression. La précision en est le secret : si le plateau trop est trop éloigné de la tête d’extrusion, l’adhérence sera mauvaise. À l’inverse, si elle est trop proche, la buse ne coulera pas et elle risquera de se boucher. Le pire est que dans tous ces ajustements, la différence réside dans un simple millimètre d’écart!

1. DittoPro, de Tinkerine

Lorsqu’il est question de cette imprimante, la première qualité de l’appareil est certainement qu’elle est fabriquée au Canada. En effet, Tinkerine est une entreprise basée à Vancouver, ce qui peut laisser croire que les pièces nous parviendront rapidement, en plus de pouvoir transiger avec eux en dollars canadiens.

D’un simple regard lorsqu’elle fonctionne, un point saute aux yeux : l’accent est mis pour mettre en valeur l’objet imprimé. En effet, le devant de l’imprimante est complètement ouvert et bien éclairé grâce à un éclairage à diodes électroluminescentes. Les élèves peuvent voir les différentes étapes de l’impression et avoir accès au plateau d’impression rapidement et directement. Il faut cependant que ces derniers évitent de toucher au mécanisme au risque de se brûler peut-être plus facilement qu’avec d’autres modèles. Il n’en demeure pas moins que la DittoPro en met plein la vue aux élèves.

L’impression au PLA se fait sur une plaque de verre non chauffée. Dans notre cas, l’appareil a été utilisé dans un petit espace de bureau et pratiquement aucune odeur n’était perceptible. Idem pour son bruit de fonctionnement : mis à part les ventilateurs, force est d’admettre que le module d’impression est discret. Il ne risque pas de déranger la dynamique de classe.

Notez que la DittoPro n’est pas connectée à l’ordinateur et seule une fente pour une carte SD est disponible devant l’appareil. Cela n’est pas idéal en éducation puisqu’il faut s’assurer que les élèves ont tous une carte SD. En cette ère de l’infonuagique, Tinkerine aurait pu prévoir brancher son imprimante à un réseau sans fil. La compagnie affirme cependant que ce choix a été fait pour éviter que l’impression ne s’arrête lorsque l’ordinateur tombe en veille. De plus, bien que la navigation dans l’écran de contrôle soit simple d’utilisation, le bouton à molette pour naviguer dans les menus doit être revu, car il y a un décalage entre son activation et ce qui se passe à l’écran. Enfin, lorsqu’un carte SD est utilisée, l’écran indique le temps restant avant que l’impression soit terminée. Cela est très pratique et contribue à faciliter la planification de l’utilisation pédagogique de l’imprimante.

En bref, l’imprimante en question est simple d’utilisation et son mécanisme n’a rien d’une construction très complexe. Malgré tout, sachant que les imprimantes 3D sont relativement fragiles, il est grandement souhaitable de faire affaire avec un distributeur local. Voxel Factory est le distributeur officiel pour Tinkerine au Québec et dans l’Est du Canada. Basée à Montréal, l’entreprise effectue l’entretien et la réparation des imprimantes 3D à un taux de 50 $/heure (ou 35 $/heure si le client a acheté l’appareil chez elle). Les locaux sont situés à proximité du pont Jacques-Cartier, dans le quartier Hochelaga.

Appréciation générale :

Simple à utiliser, nous n’avons jamais eu besoin d’en calibrer le plateau. Relativement robuste, l’éclairage et l’accès au plateau d’impression mettent en valeur le travail de l’imprimante. Nécessite plus de produits pour garantir l’adhérence (ruban et fixatif). Excellent rapport qualité-prix.

Spécifications :

- Dimensions de l’imprimante : 37 x 39 x 43,6 cm

- Poids de l’imprimante : 10 kg

- Volume d’impression : 22 x 16,5 x 22 cm (7986 cm3)

- Résolution : entre 50 et 200 μm

- Connectivité : carte SD, USB (moyennant l’installation de pilotes de tierce partie)

- Compatibilité : Mac ou PC

- Matériel : PLA (1,75 mm de diamètre)

- Prix du filament : entre 40 $ et 80 $ pour une bobine de 750 g.

- Prix de détail suggéré : 2000 $

- Rabais éducationnel : 100 $/imprimante de rabais offert chez Voxel ou 200 $/imprimante de rabais à l’achat de trois imprimantes ou plus.

- Garantie de base : 1 an

Site Web du revendeur : https://www.voxelfactory.com

Site Web du fabricant : http://tinkerine.com

2. Mojo, de Stratasys

Cette imprimante 3D est certainement le modèle le plus avancé de ceux qui ont été retenus aux fins de comparaison pour les milieux scolaires. La grande particularité de la Mojo, fabriquée aux États-Unis par Stratasys, est qu’elle imprime à l’aide de deux rouleaux de filament confinés dans des cartouches distinctes. Le premier est en polymère ABS+ et le second est un filament de support qui est soluble dans l’eau. Ce dernier filament permet l’impression d’une structure pour supporter l’impression de formes différentes présentant de fortes inclinaisons. Elle permet donc l’impression d’une plus grande gamme d’objets, et ce, même si son volume d’impression est plus petit que celui de ses concurrentes.

Vu l’utilisation de l’ABS comme filament, l’enceinte d’impression est chauffée, ce qui annule le risque de déformation de la pièce imprimée. Le tout est sécurisé et inaccessible aux élèves, ce qui enlève le danger de brulure pendant l’opération. Les élèves peuvent cependant observer l’évolution de la création de la pièce à travers une petite fenêtre donnant un accès visuel frontal à l’enceinte éclairée. Également, Stratasys offre une station de nettoyage Wavewash dans laquelle la pièce peut être plongée dans de l’eau chauffée en circulation, ce qui facilite la dissolution du filament de support. Également, lors du remplacement de la cartouche, une nouvelle tête d’extrusion est fournie afin de la remplacer pour toujours s’assurer d’une impression de qualité et, bien sûr, diminuer les risques de blocage. À chaque changement de cartouche, c’est un peu comme si on avait une nouvelle imprimante.

La Mojo n’est compatible qu’avec un ordinateur PC, auquel elle est connectée via un simple câble USB. Le cout de remplacement des cartouches est particulièrement élevé puisqu’une nouvelle tête d’extrusion est fournie; cela assure cependant un entretien minimal en limitant le risque d’engorgement de la pièce.

Stratasys est une entreprise du Minnesota qui se spécialise dans les imprimantes 3D industrielles ou commerciales, lesquelles sont souvent utilisées par des bijoutiers, des ingénieurs ou des artistes. Elle est distribuée au Québec par SolidXperts, basé à Montréal dans l’ouest de l’île, entreprise qui assure également le service d’entretien de ces imprimantes. Pour un plan d’entretien et une prolongation de la garantie d’un an, il faut prévoir 600 $US annuellement.

En somme, la Mojo de Stratasys est la porte d’entrée vers des projets pédagogiques plus complexes et mieux finis, probablement de nature artistique ou entrepreneuriale. C’est un pas dans la bonne direction pour la fabrication d’objets qui pourraient être commercialisés par des élèves menant un projet personnel ou qui font partie de diverses activités entrepreneuriales.

Appréciation générale :

Définitivement, la Mojo est une imprimante de qualité supérieure. Le fait de pouvoir imprimer des objets avec des pentes prononcées grâce au filament de support dissoluble est un atout. Cependant, le prix demeure élevé pour les besoins des élèves et les moyens des écoles. Modèle davantage orienté vers la clientèle corporative.

Spécifications :

- Dimensions de l’imprimante : 63 x 45 x 53 cm

- Poids de l’imprimante : 27 kg

- Volume d’impression : 12,7 x 12,7 x 12,7 cm (2048 cm3)

- Résolution : 170 μm

- Connectivité : USB

- Compatibilité : PC

- Matériel : ABS+ (3 mm de diamètre)

- Prix du filament : 399 $US pour une bobine de 1350 g.

- Prix de détail suggéré : 5995 $US incluant la station de nettoyage Wavewash

- Garantie de base : 1 an

Site Web du revendeur : http://www.solidxperts.com/fra/

Site Web du fabricant : http://www.stratasys.com/fr

3. Replicator (5e génération), de Makerbot

Makerbot est certainement un des fabricants les plus connus dans le domaine de l’impression 3D. D’ailleurs, l’entreprise a été rachetée par Stratasys en 2013 pour pouvoir mettre un pied dans le marché des imprimantes 3D accessibles à tous les consommateurs. Cela assure un certain accès aux pièces et la disponibilité d’une aide technique.

Malheureusement, bien que cette compagnie soit reconnue comme l’une des pionnières de l’impression 3D, Makerbot a éprouvé ces dernières années d’importantes difficultés au niveau de l’extrudeur de plastique qui se bouchait fréquemment. Heureusement, le nouvel extrudeur (Smart extruder +) remédie à la situation, en plus d’ajouter une dimension spectaculaire à l’imprimante. En effet, non seulement il arrête l’impression en cours s’il manque de filament, mais il avertit l’usager sur son téléphone intelligent de la situation. L’imprimante reprend ensuite là où elle a laissé. Une autre particularité intéressante : l’imprimante est dotée d’une caméra dans l’enceinte d’impression. On peut donc se connecter à l’imprimante pour constater visuellement l’avancement de l’impression, des fonctions qui seront certainement appréciées par les élèves!

L’imprimante a un aspect robuste et, comme Makerbot se plait à le rappeler, il s’agit d’une cinquième génération. On voit clairement que c’est un appareil évolué. Entre autres, cela s’exprime à travers un grand écran de contrôle activé par une molette précise et robuste. L’éclairage à DEL coloré est efficace et complète bien la silhouette noire de l’imprimante. On retrouve sur son boitier les informations de base pour l’impression : pourcentage de réalisation de la tâche, temps d’impression et temps restant, image du produit fini, etc. Ces informations sont également disponibles sur l’application mobile de Makerbot.

La bobine de filament est insérée à l’arrière de l’appareil, dans un compartiment prévu à cet effet; elle n’est donc pas apparente. Cela ajoute à l’esthétisme du produit. Une petite fenêtre est aménagée pour voir la quantité restante de filament dans la bobine.

Tout comme la Mojo de Stratasys, la Replicator est également distribuée au Québec par SolidXperts.

Appréciation générale :

La connectivité de cet appareil est fantastique. Il se branche aisément au réseau Wi-Fi et les tâches peuvent être envoyées sans fil à l’imprimante. La caméra est un atout pour permettre aux élèves de voir où en est rendu leur projet. Cependant, l’imprimante est particulièrement bruyante, ce qui risque de déranger le déroulement régulier d’un cours.

Spécifications :

- Dimensions de l’imprimante : 52,8 x 44,1 x 41 cm

- Poids de l’imprimante : 16 kg

- Volume d’impression : 25,2 x 19,9 x 15 cm (7522 cm3)

- Résolution : 100 μm

- Connectivité : USB, réseau, Wi-Fi

- Compatibilité : Mac, PC, Linux, iOS, Android

- Matériel : PLA (1,75 mm de diamètre)

- Prix du filament : 48 $US pour une bobine de 900 g ou 430 $US pour 10 bobines

- Prix de détail suggéré : 2899 $US ou 3887,99 $US pour un combo imprimante, 10 bobines de filament et un an supplémentaire de garantie et de service.

- Rabais éducationnel : Il n’existe pas de prix éducationnels, mais il existe des promotions occasionnelles.

- Garantie de base : 6 mois. Garantie prolongée disponible pour 1 an (350 $US), 2 ans (720 $US) et 3 ans (1105 $US). La garantie inclut une assistance technique téléphonique via Makerbot et le prix des pièces. Cela exclut le service d’un professionnel.

Site Web du revendeur : http://www.solidxperts.com/fra/

Site Web du fabricant : http://www.makerbot.com

4. L’Ultimaker 2+

Ce modèle d’imprimante 3D rappelle un peu les premiers modèles fabriqués avec un look un peu plus rétro que ses concurrents : une carcasse de métal gris brossé avec des panneaux de plastique givrés rivetés sur les deux côtés ainsi que sur le derrière de l’appareil. En revanche, le dessus et le devant de l’appareil sont complètement ouverts, ce qui permet un court, mais facile accès à l’espace d’impression. Elle offre un des meilleurs volumes d’impression des imprimantes présentées dans cette chronique. L’enceinte est également bien éclairée à l’aide de diodes électroluminescentes.

Point intéressant : la Ultimaker 2+ charge le filament par elle-même. Il suffit de placer la pointe du filament dans l’orifice derrière la machine et de sélectionner le menu de chargement du matériel sur l’écran et le tour est joué. Selon le fabricant, cette fonction permet de garder le filament le plus loin possible de la poussière.

Également, l’Ultimaker2+ est très polyvalente puisqu’elle peut varier les matériaux utilisés : PLA ou ABS. Son plateau d’impression est donc chauffé. Il faut cependant s’assurer de procéder à la calibration du plateau avant les impressions, car le plateau semble se désajuster facilement. D’ailleurs, si le plateau est mal calibré, la première couche d’impression n’adhère tout simplement pas. Également, l’imprimante est offerte avec un assortiment de quatre buses (0,25 mm, 0,4 mm, 0,6 mm et 0,8 mm) qui se changent facilement par simple dévissage manuel avant l’impression. Cela permet d’augmenter le niveau de précision de l’impression.

L’imprimante fonctionne bien, mais elle est un peu plus bruyante. Quelques bips retentissent lorsque la d’extrusion change brusquement de direction. La connexion électrique en arrière de l’appareil pourrait être revue; le connecteur ressemble à un ancien fil S-Video, ce qui n’est pas facile à connecter.

La connectivité de l’appareil est rendue possible grâce à une fente SD, mais aussi grâce à un câble USB.

Ultimaker est distribué au pays par Shop3D, entreprise basée en Ontario. Le service en anglais est impeccable et prompt, même s’il demeure difficile de dépêcher des techniciens sur place au Québec.

Appréciation générale :

Lors de l’essai, il aura fallu ajuster le plateau à plusieurs reprises et tenter notre chance plusieurs fois, mais une fois le bon ajustement trouvé, tout était impeccable. Également, ce modèle est plus versatile pour ainsi satisfaire les besoins de plusieurs utilisateurs à la fois. Décoller la pièce du plateau d’impression est également un jeu d’enfant une fois l’impression terminée. Enfin, le fait d’utiliser un filament de diamètre plus grand semble offrir une faciliter de manipulation de la bobine, et donc l’approvisionnement.

Spécifications :

- Dimensions de l’imprimante : 49,2 x 34,2 x 55,8 cm

- Poids de l’imprimante : 11 kg

- Volume d’impression : 22,3 x 22,3 x 20,5 cm (10 194 cm3)

- Résolution : entre 20 et 600 μm

- Connectivité : USB, Wi-Fi, carte SD

- Compatibilité : Mac, PC, Linux

- Matériel : ABS et PLA (2,85 mm de diamètre)

- Prix du filament : 50 $ pour une bobine de 750 g.

- Prix de détail suggéré : 3625 $ (incluant la livraison et un entretien préventif)

- Garantie de base : 1 an pièces et main d’œuvre (excluant la tête d’extrusion)

- Garantie prolongée : deux années supplémentaires pour environ 750 $ annuellement

Site Web du revendeur : http://shop3d.ca

Site Web du fabricant : https://ultimaker.com

5. La Cube Pro Trio, de 3D Systems

À plusieurs égards, la Cube Pro Trio est une imprimante qui est différente des autres imprimantes de ce banc d’essai. Dans un premier temps, elle est beaucoup plus grosse et plus lourde. Cela fait en sorte qu’elle peut imprimer de plus grosses pièces, mais, en même temps, elle prend plus de place dans la classe et elle se déplace moins facilement. Ensuite, elle permet l’impression à trois couleurs (ou à deux couleurs pour le modèle Duo, ou à une couleur pour le modèle de base) grâce à trois extrudeurs qui font partie de la même tête d’impression. Il s’agit d’une imprimante plus versatile puisqu’elle peut être utilisée avec trois types de filaments (ABS, PLA et nylon) en plus d’un filament dissoluble qui sert de support temporaire à l’impression de formes fortement inclinées. Enfin, toute la magie opère à l’intérieur de la machine : le filament s’y trouve et s’y déploie dans les tubes. L’enceinte est également chauffée pendant l’impression et cette chaleur est réglée automatiquement par une petite puce située dans la cartouche de filament. Bref, cette puce informe la machine et le logiciel du type de filament qu’elle contient et de la couleur de ce dernier. Puisque que le PLA nécessite moins de chauffage que l’ABS ou le nylon, il y a moyen d’ouvrir la porte devant l’imprimante et de retirer le panneau supérieur et celui derrière pour avoir un bon aperçu du déroulement de l’opération.

L’imprimante offre un degré d’automatisation intéressant, nécessitant moins de manipulation de la part des usagers. Le logiciel fourni est complet, quoique moins intuitif et convivial que d’autres. Une colle spéciale est fournie avec la machine et elle doit être appliquée sur le plateau d’impression. Une fois l’opération terminée, la plaque n’a qu’être rincée et elle est prête à nouveau à l’emploi.

Cette imprimante offre trois niveaux de résolution et trois options de remplissage réglables à l’aide du logiciel et peu importe les choix faits, l’impression se déroule relativement bruyamment. Cela s’explique par le fait que le plateau d’impression bouge de concert avec la tête d’impression lors de l’opération. Comme l’imprimante est carrément un cube (d’où le nom du modèle) et qu’une partie de la structure fermée semble robuste, nous serions en droit de nous attendre à un certain niveau d’insonorisation. En revanche, la qualité de l’impression est excellente. Point à souligner : l’impression en ABS s’est déroulée sans aucune odeur.

Les imprimantes de la gamme Cube sont fabriquées par 3D Systems et distribuées au Canada par Konica Minolta. La garantie de base est d’une année, mais elle couvre les pièces seulement. Elles doivent donc être changées par l’utilisateur à l’aide d’un service téléphonique basé aux États-Unis.

Les cartouches sont scellées pour préserver le filament de l’humidité. Si l’installation de ces cartouches est relativement simple, leur retrait implique un certain gaspillage de matériel puisque ce qui est retiré de l’imprimante ne peut être rembobiné dans la cartouche. Cela est particulièrement triste, surtout étant donné que les cartouches sont plus dispendieuses que celles de la compétition et qu’il est impossible de les remplacer par du filament d’un autre fabricant. Cependant, pour ceux qui ont des considérations écologiques, 3D Systems offre un service de recyclage des cartouches, du filament non utilisé ainsi que des pièces imprimées. Il ne suffit qu’à envoyer le tout par la poste à l’une de leurs usines de recyclage de Caroline du Sud ou d’Allemagne.

Appréciation générale :

Cette imprimante offre un immense espace de conception et donne une grande impression d’innovation technologique au niveau de la gestion des cartouches. Cependant, leur chargement n’est pas simple puisqu’il se fait à l’intérieur de la machine, dans un espace exigu; si vous avez de grosses mains, cela ne sera pas une expérience agréable!

Spécifications :

- Dimensions de l’imprimante : 57,8 x 59,1 x 57,8 cm

- Poids de l’imprimante : 11 kg

- Volume d’impression : 20,04 x 23 x 27,04 cm (12 463 cm3)

- Résolution : entre 70 et 300 μm

- Connectivité : USB, WiFi

- Compatibilité : Mac, PC

- Matériel : ABS, PLA et nylon (1,75 mm de diamètre)

- Prix du filament : 132 $ pour une bobine de 670 g (cartouche scellée)

- Prix de détail suggéré : 5279 $ (excluant les frais de livraison de 120 $)

- Garantie de base : 3 mois pièces et main d’œuvre (excluant la tête d’extrusion)

- Garantie prolongée : 9 mois (398 $), 2 années (664 $) et 3 années (1063 $)

Site Web du revendeur : http://konicaminolta.ca/business/products/3d-printers/index.html

Site Web du fabricant : http://www.3dsystems.com/

Questions fréquemment posées à propos des imprimantes 3D

1. Combien coûte l’impression d’une pièce?

Évidemment, c’est la première question qui vient en tête, car il peut s’avérer dispendieux de permettre l’accès à l’imprimante à tous les élèves sans contrôle. Une simple formule peut être appliquée :

(Prix de la bobine / poids de la bobine) x poids de la pièce produite = prix de la pièce

À titre d’exemple, voici une petite figurine aztèque qui mesure 8 cm de hauteur, 4,5 cm de largeur et 3 cm de profondeur. Elle est remplie à 15 % à l’intérieur puisqu’il est inutile de remplir la totalité de l’objet et que cela épargne beaucoup de filament, donc des sous, sans toutefois affecter la qualité de ce dernier. Le coût moyen d’une bobine de qualité est de 50 $ pour 750 grammes de filament. Lorsqu’on imprime cette pièce de 24,5 grammes, le coût total en filament serait de 1,63 $. Cela exclut les frais de dépréciation et de maintenance de l’imprimante elle-même. À noter qu’habituellement, les logiciels de gestion de l’impression affichent le poids et la quantité de filament (en mètres) utilisée. Il est donc aisé de faire le calcul sans avoir nécessairement à faire une première impression.

2. Combien de temps dure l’impression d’une pièce?

L’impression en 3D prend du temps, ce qui est une réalité quelque peu dichotomique avec l’avènement des nouvelles technologies dans la société. En effet, nous sommes à l’ère de l’instantanéité; l’impression 3D ramènera les élèves à faire l’éloge de la lenteur et de la précision en laissant amplement de temps à l’émerveillement et au développement de la patience. Cela dit, les enseignants doivent bien planifier leurs activités en conséquence, car s’ils croient pouvoir imprimer quelques pièces pendant leur période, ils ont tout faux!

Plus précisément, le temps d’impression dépend de plusieurs facteurs :

- La grosseur de la pièce;

- Son remplissage;

- Sa complexité de conception (pentes, détails, etc.);

- La qualité (ou résolution) de l’impression;

- Les capacités de l’imprimante.

Il est donc difficile de répondre justement. Cependant, cette information est habituellement divulguée dans le logiciel de gestion de l’impression. Aussi, à titre indicatif, la figurine aztèque dont il était question précédemment aura nécessité 3h06 d’impression.

3. Est-ce possible d’imprimer plusieurs pièces à la fois ?

Oui. Il s’agit simplement d’organiser le plateau d’impression dans le logiciel en fonction des projets et le tour est joué. Cependant, n’oubliez pas deux choses : premièrement, au-delà du sentiment de maximiser l’emploi du plateau d’impression, plus vous augmentez la tâche, plus le temps d’impression augmente. Deuxièmement, assurez-vous que votre logiciel soit en mesure d’imprimer toutes les pièces en même temps et non l’une à la fois. Si une pièce est imprimée en premier, il devient difficile pour l’extrudeur de se promener adéquatement sur le plateau d’impression et cela risque fort d’occasionner des bris.

4. Peut-on imprimer la nuit?

C’est effectivement une pratique répandue qui n’est toutefois pas recommandée, et ce, pour deux raisons principales : d’une part, s’il y a un problème avec le processus, personne n’est sur place pour intervenir (pénurie de filament, blocage, enrayage, etc.). De plus, les fabricants ne recommandent pas l’utilisation de l’appareil sans surveillance, surtout étant donné qu’il implique du chauffage et la fusion de polymère.

5. Que se passe-t-il si la bobine de filament se vide durant l’impression?

Cela dépend de l’imprimante. De rares imprimantes permettent d’arrêter l’impression pour ensuite la reprendre lorsque la bobine a été changée. Les systèmes de détection de filament n’ont pas été implantés dans toutes les machines, du moins, pas pour des imprimantes à usage non commercial (excluant la Replicator de Makerbot). Dans ce cas-ci, l’extrudeur poursuit son impression, mais sans polymère. Il n’y a donc aucun système de détection d’épuisement de filament.

Cependant, les logiciels estiment habituellement la quantité et le poids de filament nécessaires à la réalisation de la pièce. En conséquence, il y a moyen de peser la bobine de filament pour avoir un aperçu de la quantité restante. Pour plus de précision, peser une bobine vide et en soustraire le poids à celle dans la machine.

6. Qu’est-ce que la résolution d’impression?

D’entrée de jeu, il importe de savoir que 1000 microns (μm) équivalent à un millimètre. Donc, plus le chiffre de résolution est petit, plus la résolution est élevée. Sur des pièces plates, cela importe peu, car la différence entre une résolution de 20 μm ou de 200 μm est imperceptible à l’œil nu. Cependant, pour les dégradés, courbes ou pentes, cela fera une différence appréciable.

La majorité des fabricants ou des experts dans le domaine recommandent une résolution de 60 μm pour la fabrication d’une pièce à haute résolution. Pour une pièce qui n’est pas destinée à un usage où l’esthétique est primordiale, par exemple pour des épreuves préliminaires, 200 μm suffisent amplement. Il ne faut pas oublier que plus la résolution est élevée, plus la durée d’impression l’est également.

7. Est-ce possible d’imprimer en deux ou trois couleurs à la fois?

Certaines machines offrent cette possibilité avec un double extrudeur (voir, entre autres, la CubePro Duo ou Trio de 3D Systems). D’autres imprimantes, quant à elles, offrent la fonction « pause » où il est possible d’interrompre manuellement l’impression pour changer le filament. Sinon, certaines pièces s’emboitent; il ne suffit que d’imprimer les différentes pièces de couleurs différentes.

Sincères remerciements :

- Monsieur Jean-François Niaison, président de SolidXperts.

- Monsieur François Lahey, copropriétaire de Voxel Factory.

- Messieurs Kenneth et Jacky Wan, copropriétaires du 3DShop.

- Messieurs Jamal Hashim et Jean-Pierre Houle de Konica Minolta, partenaires de 3D Systems